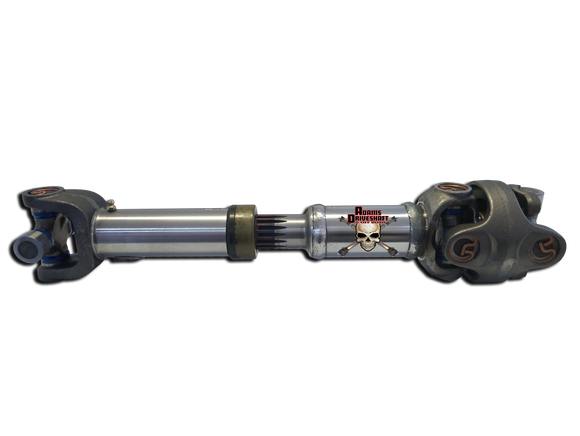

Adams 1310 vs 1350 Driveshafts

The distinction between 1310 and 1350 driveshafts centers around the load they can handle. Similar to comparing trucks where an F250 offers greater capacity and strength than an F150, the 1350 driveshaft series presents a sturdier and more resilient choice over the 1310 series. The 1310 series is typically equipped in Jeeps and light trucks, serving adequately for standard use, much like a "half-ton" joint. Conversely, the 1350 series is designed for heavier, full-size trucks, aligning with what might be termed a "one-ton" joint, ready for more rigorous demands.